-

Polyurethane Round Belt

-

Polyurethane V Belt

-

Super Grip Belt

-

Submarine Cable Protection

-

Polyurethane Rollers

-

Polyurethane Wheels

-

Screen Printing Squeegee

-

Polyurethane Rubber Sheet

-

Polyurethane Parts

-

Kevlar Belts

-

Extruded Polyurethane

-

Parallel Belt

-

Polyurethane Tubing

-

Polyurethane Timing Belt

-

PVC Conveyor Belt

-

Urethane Belt Welder

-

Mr. Alcioni possamaiCustomer satisfaction products , good service !

Mr. Alcioni possamaiCustomer satisfaction products , good service ! -

Mr.Mikewe are very impressed with the quality of the belts you produced.

Mr.Mikewe are very impressed with the quality of the belts you produced. -

Mr. joneyour products are very popular in my markets.

Mr. joneyour products are very popular in my markets.

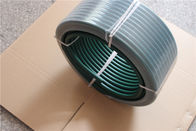

Polyurethane Flat Power Transmission Belt High Tear Strength Resistance

| Place of Origin | China |

|---|---|

| Brand Name | jiuna |

| Certification | ROHS |

| Model Number | Diameter 3mm~20mm |

| Minimum Order Quantity | 5 rolls |

| Packaging Details | Inner packing is plastic film .outer packing is carton . |

| Delivery Time | Within 5 working days After receipt of your deposit |

| Payment Terms | T/T, 50% payment in advance ,50% balance before shipment ; Western Union ; L/C |

| Supply Ability | 96.000 meters per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Color | Green Or As Your Require | Material | PU |

|---|---|---|---|

| Longth | 300m/roll 200m/roll 100m/roll | Hardness | 85A-90A |

| Tensile Rate | 0.3kg-31.3kg | Stretching Rate | 1.5%-3% |

| Main Function | Drive,transmission, | ||

| Highlight | pu round belt,pu extruded belt |

||

Polyurethane Flat Power Transmission Belt High Tear Strength Resistance

Our company specializing in the production of PU round belt,V belt,non-slip belt,wire clip,clip wire core,PU guide, stop,package edge,skirt,scraping gum,rubber roller,wheel and all kinds of non-standard special polyurethane products.

TPU proudcts characteristic and main performance are: easy adhesion,good abrasion resistance,tear resistance,bending strength,tensile strength and breaking elongation,heat-resistant moderate (-30 ℃~80℃ ) ,hardness shaw (70a~98a). Smooth round belt, V belt surface finish is good, bright color with rough surface. Uniform praticles,comfortable feel.cpu pouring product characteristics and main performance are: wear-resisting.oil,acid and alkali resistance,solvent resistance,ozone resistance,aging resistance,environmental protection,non-toxic,the main products are rubber roller plastic bags,plastic core package iron roller,printing and dyeing,etc.,and can undertake various non-standard parts processing,customized non-standard products can be according to the drawing,plastic,iron core production in a body.

TPU products are mainly used in textile,

tobacco,packaging,printing,machinery,electronics,glass,ceramics and other machinery and equipment industry,especially suitable for ceramic industry of the spool, polishing line, such as the main plays a driving, conveying,sealing and shock absorption,decoration and so on.

Transmission purposes of textile machines, packaging machines, printing presses, food machinery, industrial and paper equipments. Cut round belts can be joined as the endless belts as required according to the drive wheel distance and pulley size.

|

Items NO.Φ |

Least radius of gyration |

Stretching rate |

Maximum tensile rate |

Hardness |

Length of rolled |

||

|

DIA(mm) |

In |

mm |

% |

Kg |

Lbs |

Shore( A) |

Length of rolled |

|

2mm |

0.79 |

20 |

1.5-3% |

0.3 |

0.7 |

95 |

400 |

|

2.5mm |

0.87 |

22 |

1.5-3% |

0.4 |

0.9 |

95 |

400 |

|

3mm |

0.98 |

25 |

1.5-3% |

0.7 |

1.6 |

90 |

400 |

|

3.5mm |

1.18 |

30 |

1.5-3% |

0.95 |

2.1 |

90 |

400 |

|

4mm |

1.38 |

35 |

1.5-3% |

1.2 |

2.7 |

90 |

200 |

|

5mm |

1.57 |

40 |

1.5-3% |

2.0 |

4.3 |

90 |

100 |

|

6mm |

1.97 |

50 |

1.5-3% |

3.2 |

7.0 |

90 |

100 |

|

7mm |

2.17 |

55 |

1.5-3% |

4.1 |

9.0 |

90 |

100 |

|

8mm |

2.56 |

65 |

1.5-3% |

5.0 |

11.0 |

90 |

100 |

|

9mm |

2.95 |

75 |

1.5-3% |

6.8 |

15.0 |

90 |

50 |

|

10mm |

2.95 |

75 |

1.5-3% |

7.7 |

17.0 |

90 |

50 |

|

12mm |

3.94 |

100 |

1.5-3% |

12.2 |

27.0 |

90 |

30 |

|

15mm |

4.72 |

120 |

1.5-3% |

17.7 |

39.0 |

90 |

30 |

|

18mm |

5.71 |

145 |

1.5-3% |

25.4 |

56.0 |

90 |

30 |

|

20mm |

6.30 |

160 |

1.5-3% |

31.3 |

69.0 |

90 |

30 |

![]()

![]()